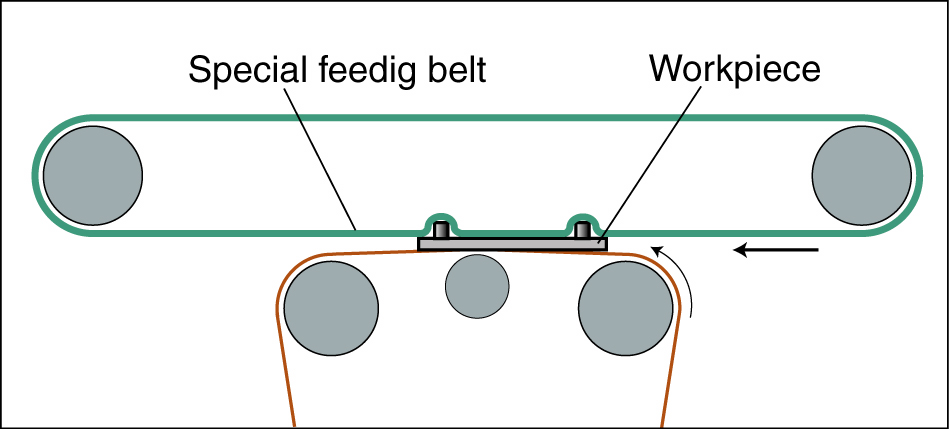

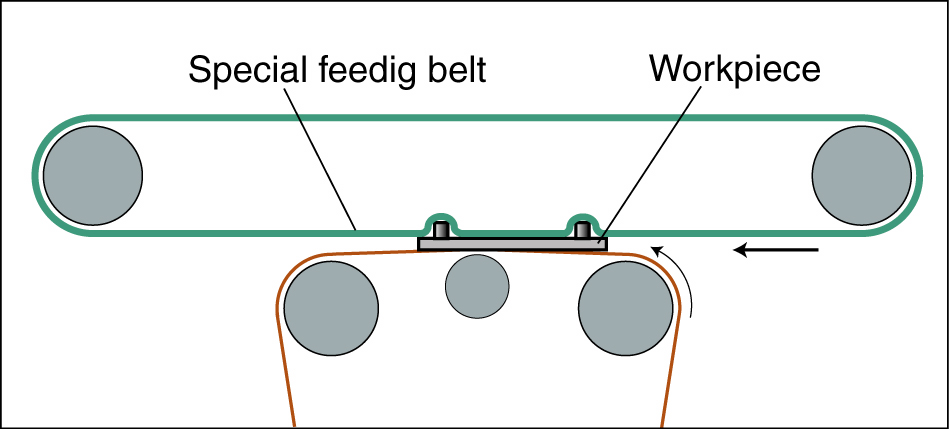

How work-piece is held and transferred

How work-piece is held and transferred

|

Features

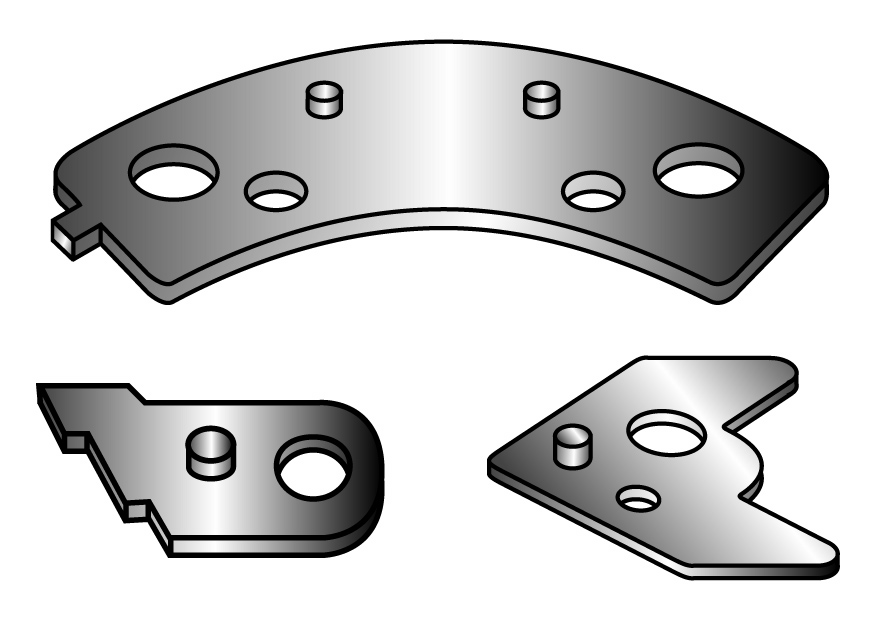

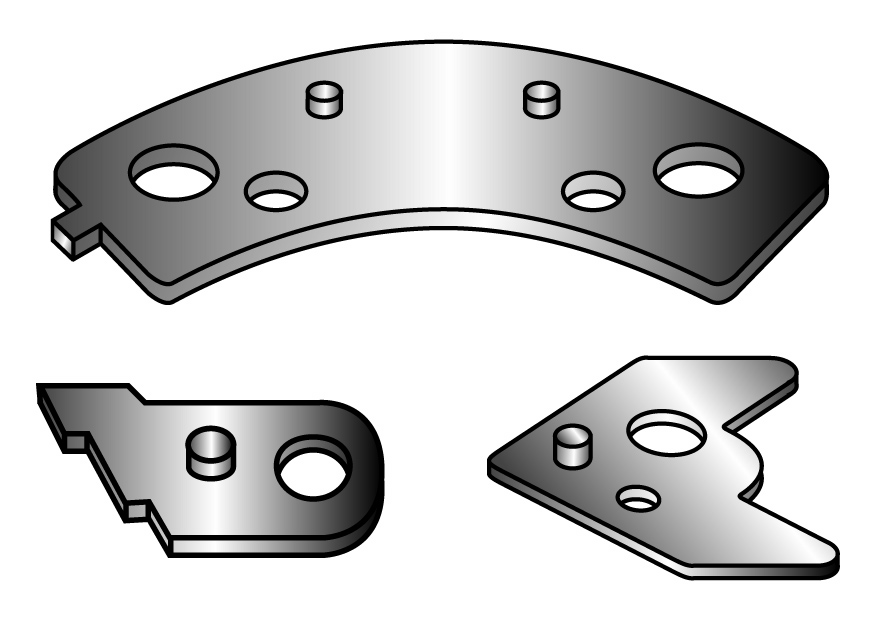

Wet system and dedicated to remove burrs on the back side

of pin projection pressed components by grinding belt.

Put pin projection side up and grinding side down, work-piece is

stably transferred.

Grinding belt release/attaching can be done within 30 seconds

and set-up time is reduced to the level that can be ignored.

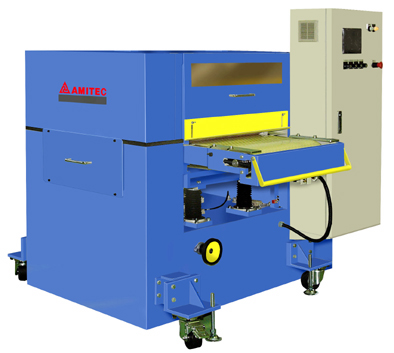

Space-saving and high speed production machine.

Best fit to production line.

| Specifications |

SSF201 |

| Max. workable width |

150 mm |

| Min. workable size |

40 mm |

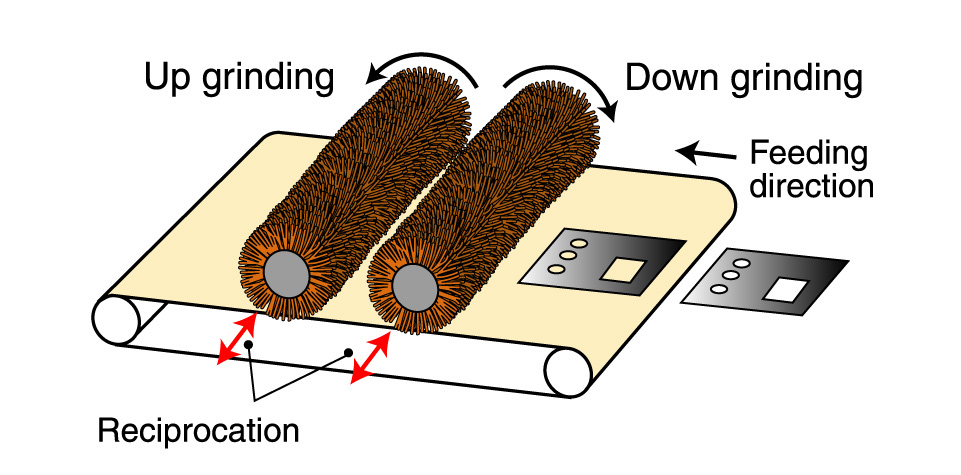

| Grinding method |

Bottom / Wet / Belt grinding |

| No. of grinding head |

1 |

| Grinding speed |

200〜600 m/min |

| Feeding speed |

3〜12 m/min |

| Grinding belt size |

200 x 1900 mm |

Machine size

(LxWxH) |

1400x1400x1707 mm |

|